Large complex machined parts are the foundation of what built Precise Tool into a leading supplier to Large OEM’s.

Our State of the Art manufacturing facility is able to turn parts with a max OD of 216” and up to 132” tall. Precise has invested in Cranes that can lift up to 60 Ton.

What our customers receive:

- Cost Competitiveness

- Tight Tolerances

- Accurate Lead-times (Red Alert available)

- Prototype and Production Runs

- Knowledgeable Machining Experts on site, made in the USA

Commonly manufactured materials include, Steel, Stainless Steel, Cast Iron, Aluminum, Space Age metals.

Our assortment of Large Diameter VTL’s are specifically designed for machining large round parts. Precise Tool & Manufacturing is equipped with cranes capable of handling up to 60 tons. All of our machinists and quality technicians work together to provide high quality parts on time, in tolerance at competitive prices.

We are able to machine:

- Castings

- Combustor Shells

- Cylinders

- Flanges

- Housings

- Compressor Rings

- Scrolls

- Blade Rings

- Valve Bodies

- Inlets

To speak with a member of our team, start a free quote or get additional information on any of the services we provide, get in touch with Precise Tool & Manufacturing today.

This 220" Diameter Cast Iron head for the mining industry weighed 45,000 lbs as cast and finished at 33,000 lbs after machining.

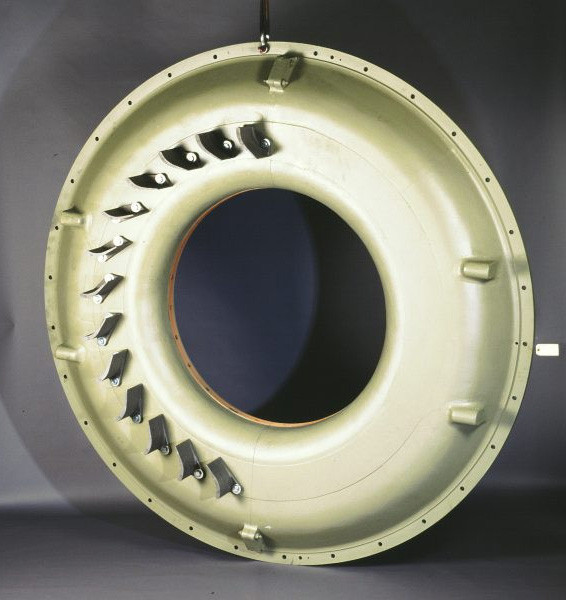

2 piece assembly gas sheild

This gas shield is 140" in diameter and weighs 3,400 pounds.

Welded yoke assembly.

This welded yoke assemble is 60" in length and 30" in diameter. The main bore is inline within .001 and the entire piece weighs 1,980 pounds.