September 9, 2018

Because there are so many uses and applications of modern milling, you can find a variety of different types and styles of milling machines. Some machines are designed for a wide range of general pieces, whereas other milling equipment is used for specialized pieces that require unique patterns. The vast majority of milling machines are designed to work with materials that are heavy and difficult to cut, such as copper alloys, titanium, and stainless steel. For most projects, an engineered model is created first and used to set the parameters of the milling machines.

At Precise Tool, we have numerous specialty milling and boring machines to build any type of custom parts. We use the best modern equipment for your project, whether you need CNC vertical milling, turning machines, or flexible manufacturing systems. An overview of the differences and advantages of vertical milling compared to horizontal milling follows.

How a Vertical Milling Machine Works

When used to describe milling machines, the terms “horizontal” and “vertical” generally refer to the orientation of the spindle or cutting tool. A spindle, also known as a cutting head, is oriented vertically on a vertical milling machine. Because the cutting head is fixed in its vertical orientation, there are other parts of the machine that shift along one or more axes to move the material so it’s in the right location to be milled correctly.

There are two basic types of vertical mills: turret and bed. They work slightly differently and provide unique benefits:

- Turret Mill: In a turret mill, the spindle remains in a fixed location, and the bed portion of the machine that holds the material moves horizontally or vertically. With the ability to manipulate the position of the material in both directions, a turret mill is extremely versatile. However, these mills are usually limited to projects relating to smaller pieces, as the two-axis movement can be challenging with larger pieces of material.

- Bed Mill: A bed mill can only move the material along the horizontal axis. In this type of milling machine, the spindle is restricted to the vertical axis but can move up and down as needed. The movement of the spindle combined with the horizontal movement of the bed allows milling of a wide variety of shapes and depths. A bed mill is better suited to projects requiring heavy, large pieces than a turret mill is.

Applications and Benefits of Vertical Milling

While many projects can be worked on either a vertical or horizontal mill, each type can offer unique advantages for certain milling specifications. Vertical milling is an excellent choice for projects mostly worked on a single side, such as sinking dies and working with large metal plates. In some cases, vertical mills are simpler and less complex internally than horizontal mills, because the spindle doesn’t have to be geared to move in two directions. Some vertical milling projects are more affordable than those requiring horizontal milling.

Operation of a Horizontal Milling Machine

In contrast to vertical milling equipment, horizontal milling machines don’t use a fixed spindle. Instead, they employ cutting heads similar to small circular saws that are mounted on a horizontal arbor. In some cases, such as when the arbor stretches across the entire length of the bed, multiple cutters can be installed. While some mills restrict the movement of the bed to the horizontal plane, others have rotating beds. These machines can provide milling at different angles.

Advantages of Horizontal Milling for Specific Projects

There are several projects that work best on horizontal milling machines:

- Cutting one or more grooves in a material

- Creating slots

- Completing projects that require working on multiple sides and/or in several planes

- Working large projects utilizing extremely heavy material

Generally, horizontal milling is a better choice for complex projects than vertical milling. These machines can often complete tasks faster, although projects requiring this sort of precise and complex work may require a larger financial investment than projects that can be worked on vertical mills.

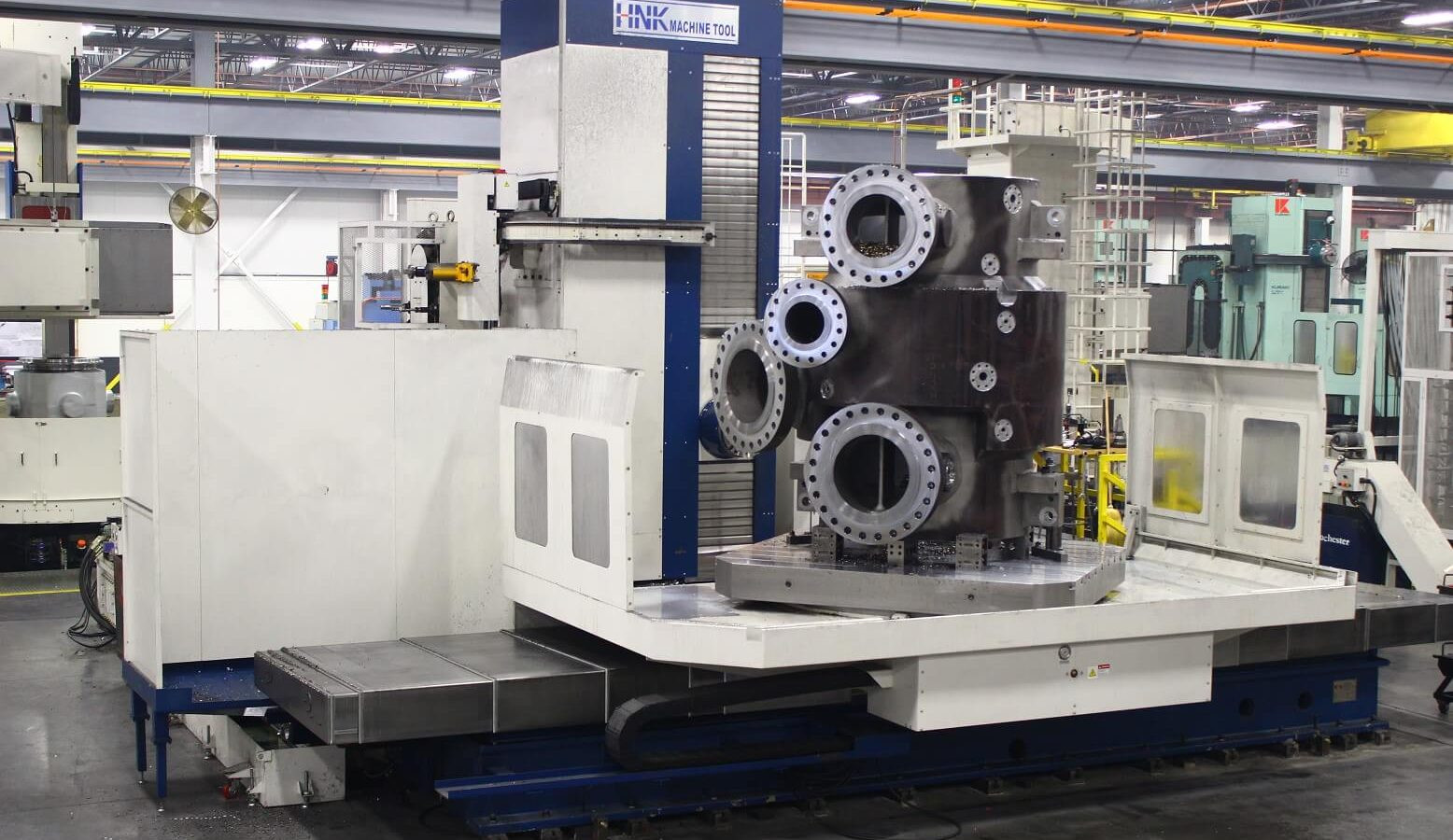

Machines for Large Milling Projects

Projects that require extremely large parts are best worked on large milling machines specially designed for such materials. Some of these projects include big and heavy cast components, plates, and fabricated weldments. Our large milling machines can handle projects requiring material up to 40 feet in length and 60 tons in weight and can provide the right capabilities for this sort of machining.

Build Your Part On Our Milling Machines

At Precise Tool, we know that the best equipment and top-notch manufacturing personnel make completing a project faster. Our in-house engineering department can work with you to develop extremely accurate models. Then, we use custom tool heads and cutters to complete your projects in the most accurate and time-efficient manner possible.

Many of our high-quality, accurate milling machines utilize convenient modern technology, including CNC. We can also design and create a customized tool for your project if necessary. With our equipment and expertise, we can help you complete your machining work quickly without sacrificing quality. To request a quote, contact us today.